Discovery

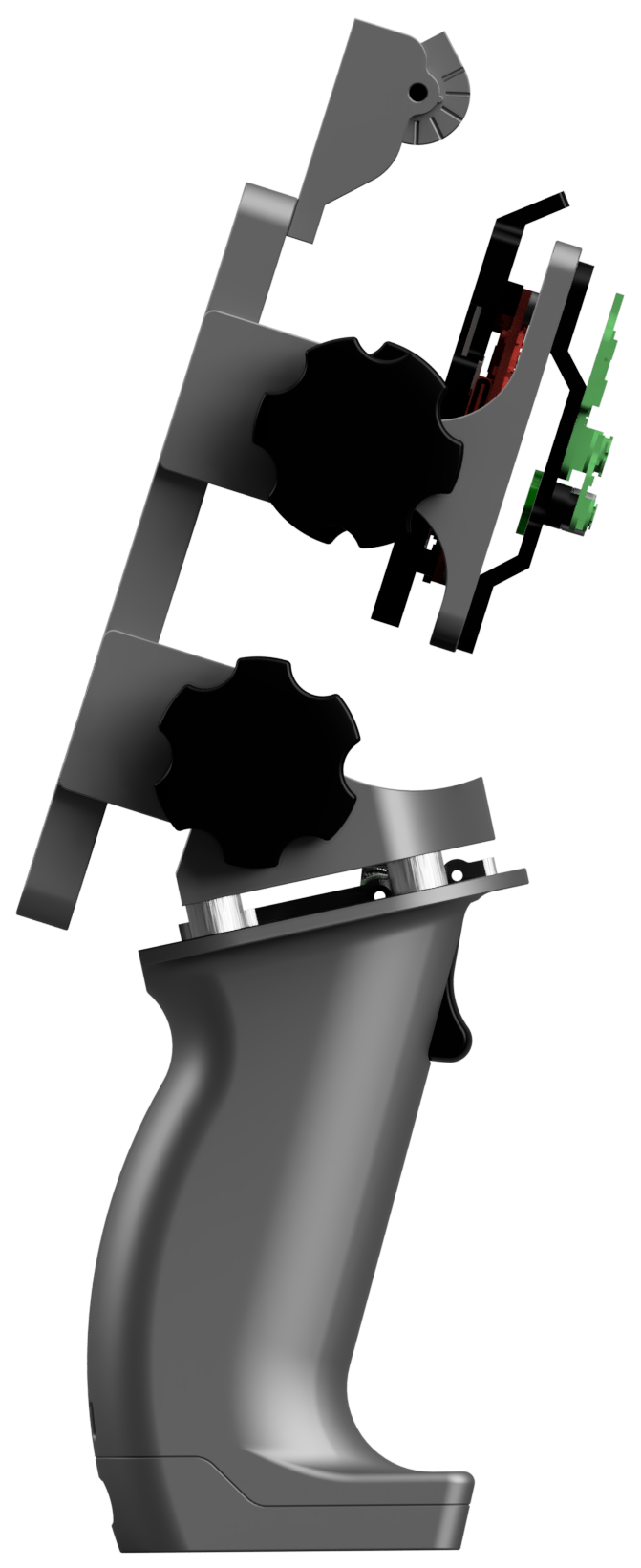

The rise of e-commerce convinced us that there was a need for a rugged handheld tool capable of counting, inspecting, and creating 3D models of products.

As we reached out to potential customers, visited their facilities, spoke with workers on the line, and experienced their workflows firsthand, the image of the tool that we would want to use ourselves was brought evermore into focus.

For most of the lifecycle of this project, I owned industrial design, mechanical design, and stress testing.